.jpg)

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

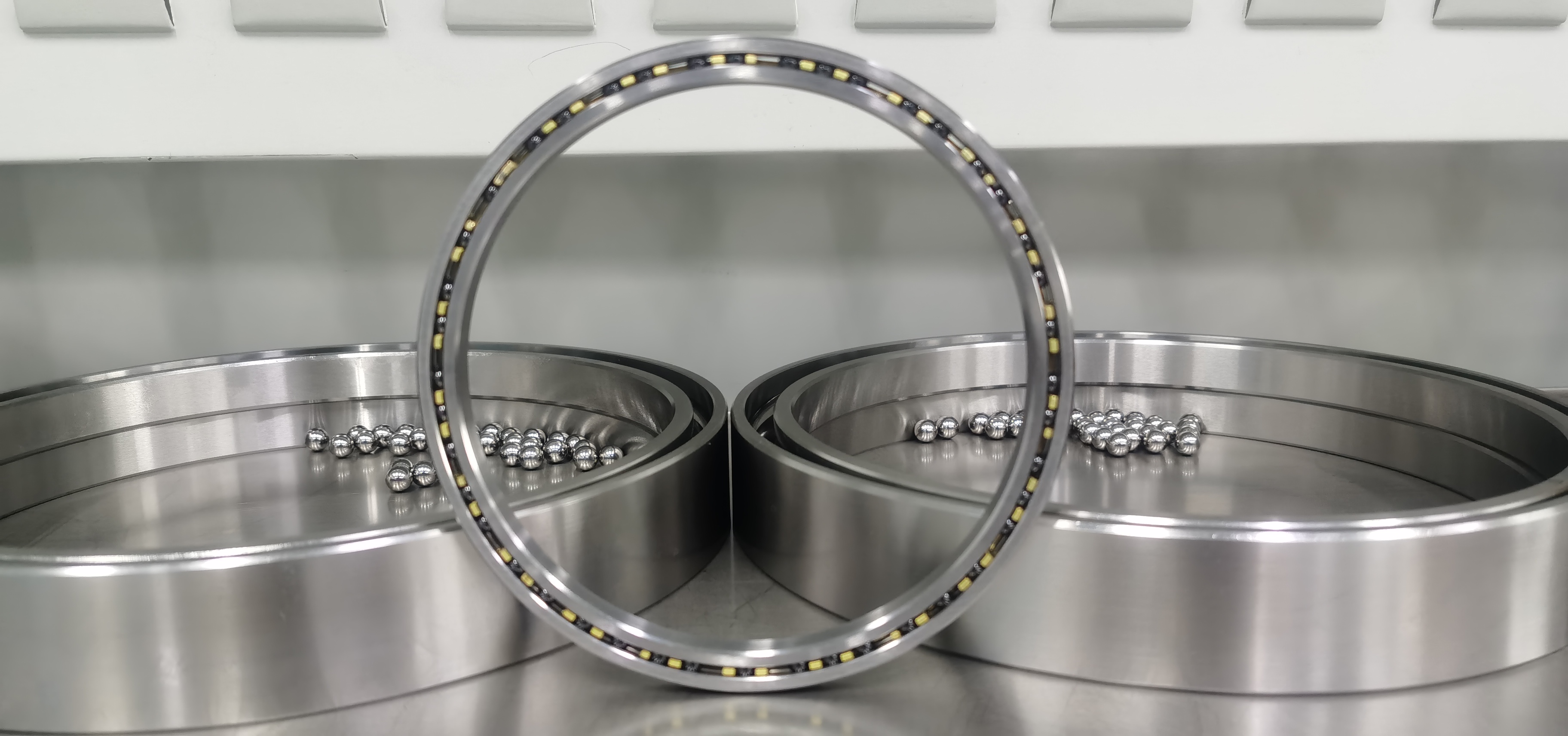

- Thin Section Bearings

Thin section bearings are a type of rolling bearing designed to meet specific needs, characterized by their very small cross-sectional size. Regardless of the inner and outer diameter, the cross-section remains nearly constant, giving thin section bearings unique properties compared to other types of bearings, especially in applications that require space-saving, lightweight, and high precision.

Structural Features of Thin Section Bearings

Thin section bearings consist of an inner ring, an outer ring, rolling elements (usually steel balls), and a cage. The cross-section is designed to be very small, and it remains consistent even when the inner or outer diameter changes. This structure provides significant advantages in weight reduction and space-saving while maintaining good load-carrying capacity and high precision.

Thin section bearings typically come in three basic types: deep groove ball bearings, four-point contact ball bearings, and angular contact ball bearings. Each type has distinct characteristics to suit different application scenarios. For example, four-point contact ball bearings can handle bidirectional axial loads, making them ideal for space-saving applications.

Differences Between Thin Section Bearings and Traditional Bearings

-

Cross-Section Size: Thin section bearings have a very small cross-section that remains unchanged as the inner and outer diameters vary. In contrast, the cross-section of traditional bearings usually changes with the inner and outer diameters.

-

Lightweight: The lightweight design of thin section bearings makes them ideal for applications where reducing overall equipment weight is crucial, such as in robotics and aerospace systems. Traditional bearings, on the other hand, can be too bulky for these applications.

-

High Precision and Rigidity: Due to their small cross-section and special structural design, thin section bearings provide high precision and sufficient rigidity, making them suitable for high-precision applications, such as surgical robots in medical equipment and manipulators in industrial automation.

-

Space-Saving: Thin section bearings are designed to minimize space usage, making them an ideal choice for devices requiring compact designs, such as precision instruments and robotic joints. Traditional bearings usually require more installation space.

Applications of Thin Section Bearings

The unique design of thin section bearings makes them widely used in many fields:

-

Robotics: Thin section bearings are commonly used in robotic joints, where their lightweight design and high precision enable flexible movements and reduced energy consumption.

-

Aerospace: Thin section bearings are used in satellites, aircraft, and other aerospace systems, providing reliable performance while effectively reducing equipment weight.

-

Medical Equipment: In CT scanners, MRI machines, and surgical robots, the low friction, smooth operation, and high precision of thin section bearings help improve the accuracy and lifespan of the equipment.

-

Industrial Automation: Thin section bearings are used in automated production lines and robotic arms to support high-speed and high-precision operations, helping to enhance overall production efficiency.

In summary, with their unique small cross-sectional design, lightweight, high precision, and space-saving features, thin section bearings offer significant advantages over traditional bearings. They play an irreplaceable role in fields such as robotics, aerospace, medical equipment, and industrial automation. Choosing the right thin section bearing can not only enhance equipment performance but also significantly reduce weight and space requirements, providing better solutions for precision mechanical design.

Luoyang Nice Bearing can provide you with precision thin section bearing products according to customers' special design and requirements, welcome to inquire!

- Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- sales@lynicebearing.com

- techsupport@lynicebearing.com

- +86-0379-60689957

- +86-0379-60689929

- Nettie.Ma